STE Highlights, September 2020

Awards and Recognition

Materials Science and Technology

Breakthrough on recompaction of spall damage on second shock

Wang co-edits special Materials issue: Helium effects on materials in extreme environments

Awards and Recognition

Harvey honored as American Society for Nondestructive Testing Fellow

American Society for Nondestructive Testing (ASNT)

David Harvey, of Nondestructive Testing & Evaluation (E-6) was selected as a 2020 Fellow of the American Society for Nondestructive Testing (ASNT). Harvey was cited for his professional distinction and continued significant contributions to the advancement of nondestructive testing and evaluation.

Nondestructive testing is the process of inspecting, testing, or evaluating materials, components, or assemblies for discontinuities without destroying the serviceability of the part or system. In other words, when the inspection or test is completed, the part can still be used. Nondestructive testing is particularly important for LANL’s Nuclear Deterrence mission area.

Harvey will be presented with the Society pin and framed certificate at the annual ASNT conference. However, due to the pandemic, the conference will take place virtually Nov. 9–12, 2020.

Technical contact: David Harvey

Capability Enhancement

Two capability enhancements bolster experiments at LANSCE

A new experimental setup for exploring physics beyond the standard model and a new analysis coupled with an experimental instrument for stress measurements represent the latest capability enhancements at the Los Alamos Neutron Science Center (LANSCE).

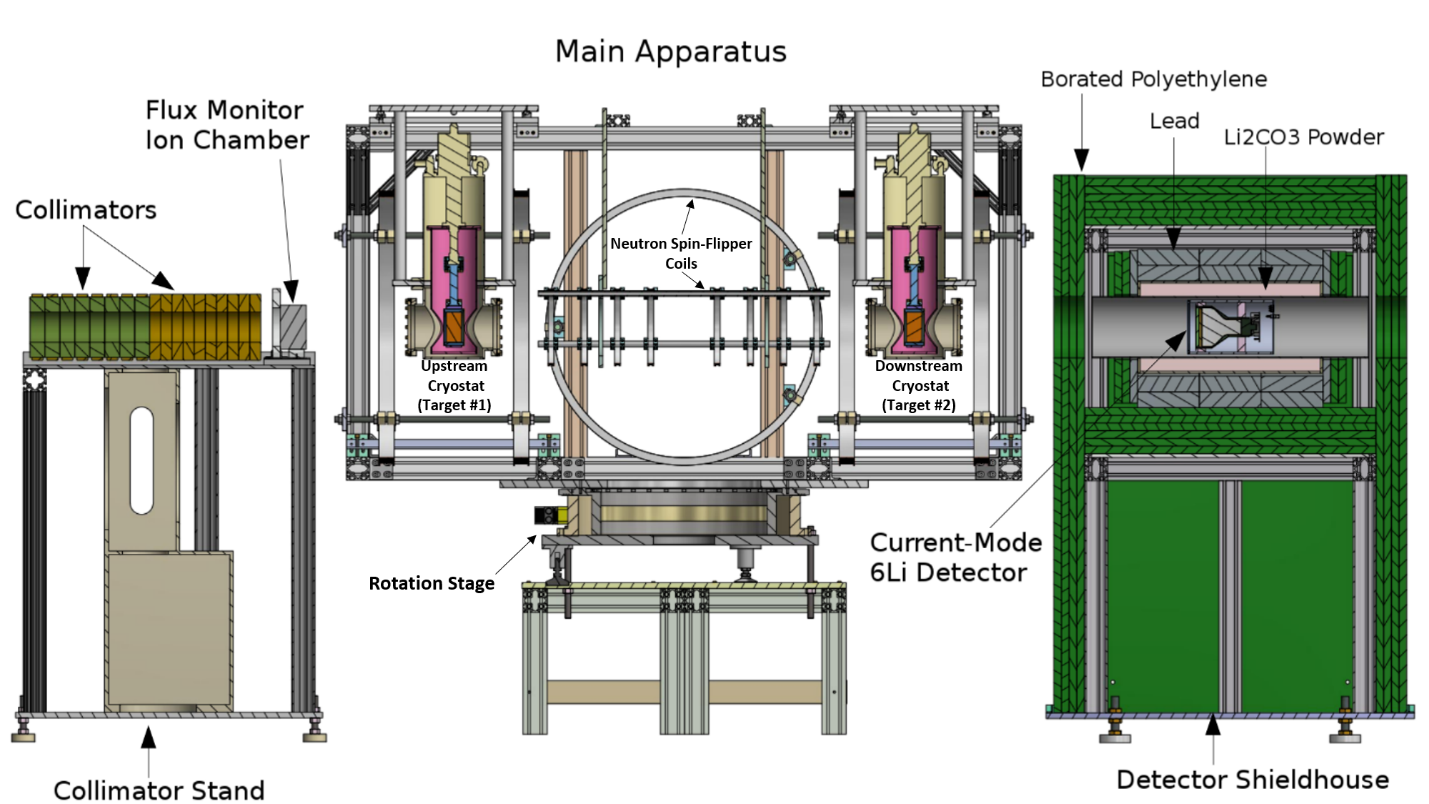

The new apparatus designed for precision parity violation studies in neutron–nucleus resonances. The setup consists of interchangeable collimation; an aluminum frame (mounted to a rotation stage), upon which are mounted two cryostats and a system of neutron spin-flipper coils; and a large shieldhouse containing a 6Li scintillator detector. Nuclear targets can be placed inside each of the two cryostats, or the upstream cryostat may be removed completely and a 3He neutron polarizer installed instead.

Investigating time-reversal violation

Researchers from Los Alamos and the University of Kentucky designed a device to conduct high-precision measurements of a specific physics phenomenon—parity violation—that occurs in certain neutron–nucleus resonance interactions. These measurements will be used as input parameters by the Neutron OPtics Time Reversal EXperiment (NOPTREX) collaboration, which aims to investigate “time-reversal violation.”

This aspect of the Standard Model applies to physical processes that do not seem to play by the same “rules” of physics if the dynamics of the system are reversed. For example, if the dynamics are thought of as moving forward in time from an initial state to a final state, time-reversal violation can be tested by reversing the final state’s conditions and seeing whether the system retraces its steps.

The Standard Model of particle physics is known to be incomplete. Completing the Standard Model will help explain many phenomena not presently understood by physicists, such as the existence of dark matter, the excess of matter over antimatter present in the universe (known as the ‘baryon asymmetry’), the neutron lifetime puzzle, and whether or not protons decay. It can also help solve more applied challenges such as the underlying nature of the nuclear forces dictating the stability of nuclear isotopes.

The novel modular apparatus these researchers built will experimentally test target materials with large amounts of parity violation present in their nuclear resonance spectra. Such a task falls at the confluence of fundamental physics and materials science. Besides understanding the nuclear interactions behind the neutron absorption resonance phenomenon, researchers must also understand how bulk phenomena can affect the measured resonance profiles. A complete understanding of both aspects is necessary to select strong candidates for the eventual time-reversal violation experiment planned by NOPTREX.

The work leverages Los Alamos expertise in neutron physics, accelerators, data acquisition and analysis, and the capability of Flight Path 12 at LANSCE’s Lujan Center. Flight Path 12 possesses an intense spectrum of cold and epithermal neutrons, energies that are less-often considered for fundamental investigations than sources such as ultracold neutrons. NOPTREX requires epithermal neutrons to leverage neutron–nucleon resonances in select nuclei. The high epithermal flux provided by FP12, coupled with the capability to measure neutron energies using neutron time-of-flight, which allows for the energy selection of specific nuclear resonances, makes FP12 ideal to conduct the NOPTREX time-reversal search and associated intermediate experiments.

Reference: “A modular apparatus for use in high-precision measurements of parity violation in polarized eV neutron transmission.” Nuclear Instruments and Methods in Physics Research, A (2020).

Los Alamos researchers: Danielle Schaper (Materials Science in Radiation and Dynamics Extremes, MST-8; University of Kentucky); Melvin Borrego Andrew Chavez, Kelly Knickerbocker, and Michael Mocko (all LANSCE Weapons Physics, P-27).

The NOPTREX collaboration includes scientists from other U.S. national labs and universities (Berea College, Eastern Kentucky University, Indiana University, Oak Ridge National Laboratory, Ohio University, Southern Illinois University, University of Kentucky, University of South Carolina, Western Kentucky University) and from Mexico, Germany, Switzerland, China, and Japan.

Technical contact: Danielle Schaper

Mixed powder sample on SMARTS.

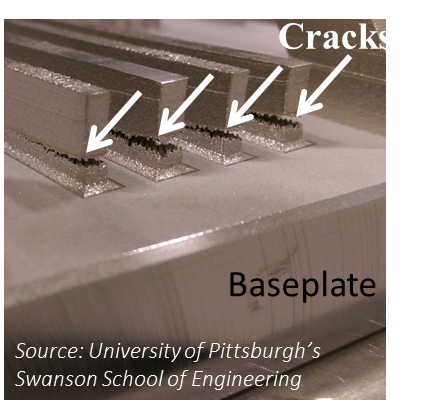

Residual stress-driven fracture during an additively manufactured build.

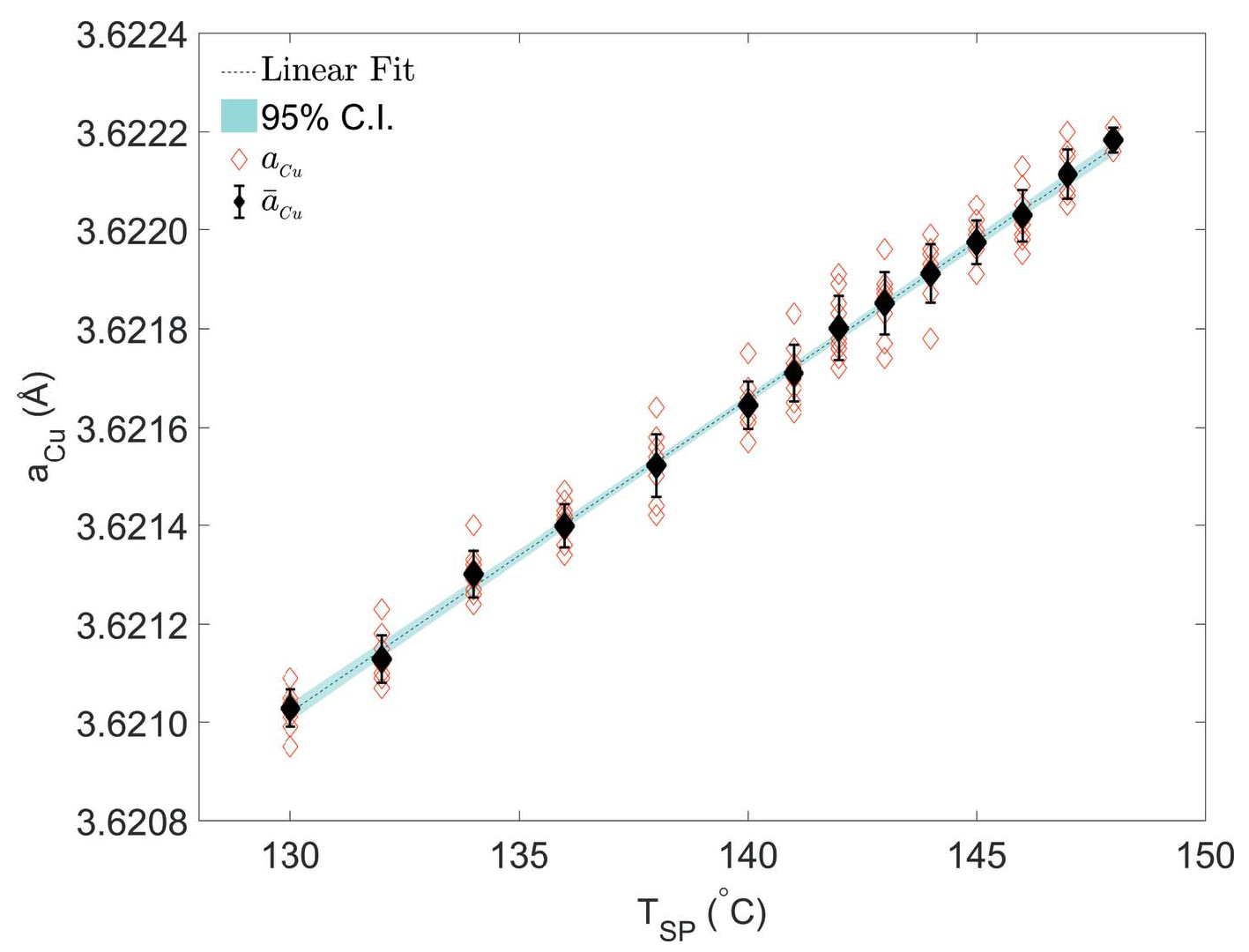

Determination of accuracy and precision of lattice measurements.

Determining uncertainty quantification in stress measurements

A team of researchers from Los Alamos, Columbia University, and Oak Ridge National Laboratory leveraged the capabilities of SMARTS, the spectrometer for materials research at temperature and stress at the Los Alamos Neutron Science Center, to quantify the precision and the accuracy of lattice parameter measurements.

Diffraction-based stress measurements usually assume some degree of uncertainty in lattice measurements based on fitting statistics alone, typically ignoring systemic sources of uncertainty. Therefore, this combination of analysis and experimental design offer important advances toward uncertainty quantification.

The researchers measured the known difference in thermal expansion on a mixed copper and silicon powder sample. They concluded the standard deviation of strain measurements on SMARTS is comparable to the fitting uncertainties frequently chosen to represent accuracy. Depending on the material, this corresponds to a 15-MPa stress uncertainty. Moreover, they identified a systematic uncertainty during the experiment, as the sample holder was not stationary during the heating and cooling, which led to a temperature-dependent geometrical-based difference between the two detector banks at SMARTS.

Their simple, statistical analysis provides a strong experimental basis for uncertainty quantification of stress measurements on weapons components in the past and in the future.

Funding and mission

Campaign 1 (LANL Program Manager Ray Tolar) funded the capability. The work supports the Laboratory’s Nuclear Deterrence mission area and the Materials for the Future capability pillar.

Reference: “Experimental determination of precision, resolution, accuracy and trueness of time-of-flight neutron diffraction strain measurements,” Journal of Applied Crystallography, 53 (2020). DOI: 10.1107/S1600576720002150

Researchers: Bjorn Clausen and Donald Brown (Materials Science in Radiation and Dynamics Extremes, MST-8); I.C. Noyan and M.K. Tippet (Columbia University); J.R. Bunn and E.A. Payzant (Oak Ridge National Laboratory).

Technical contact: Bjorn Clausen

Chemistry

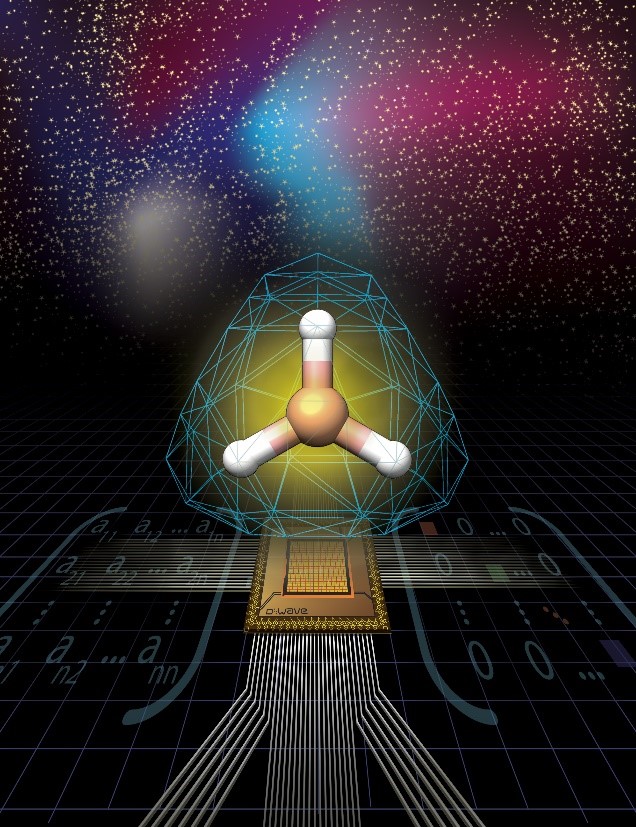

A new quantum chemistry algorithm for LANL’s D-Wave quantum annealer

Researchers from LANL’s Theoretical division (Physics and Chemistry of Materials, T-1) and Chemistry division (Inorganic Isotope and Actinide Chemistry, C-IIAC) partnered to develop a general Quantum Annealer Eigensolver (QAE) algorithm. Using LANL’s 2000Q D-Wave quantum annealer, the QAE solved the molecular electronic Hamiltonian eigenvalue-eigenvector problem, giving the ground and excited states of molecules and generating potential energy surfaces.

The Quantum Annealer Eigensolver is applied to the calculation of electronic states of a molecule. A user-generated Hamiltonian matrix is solved on D-Wave 2000Q to obtain the smallest eigenvalues and associated eigenvectors.

Foundations of quantum chemistry

“Quantum chemistry is regarded to be one of the first disciplines that will be revolutionized by quantum computing,” said Alexander Teplukhin (T-1).

To truly understand a quantum system—such as electron states, particularly of systems with more than 20 electrons—quantum computing must be employed, as the necessary calculations are intractable for classical computers. Although universal quantum computers of practical scale may be years away, various approaches are currently being pursued to solve quantum chemistry problems on near-term gate-based quantum computers and quantum annealers by developing the appropriate algorithm and software base.

The results of this current LANL research will encourage further development of software such as qbsolv, which has promising applications in emerging quantum information processing hardware and is able to address large and complex optimization problems.

The QAE algorithm

The QAE is based on the variational (Rayleigh–Ritz) method, commonly used in quantum mechanics. Given a sufficiently large number of quantum bits (or qubits), the eigenvalue problem is mapped to the classical Ising model, solvable by the current generation of D-Wave annealers.

Previously, the researchers reported QAE solving the vibrational quantum problem for diatomic and triatomic molecules. The QAE is Hamiltonian and basis agnostic, uses an efficient wave function encoding scheme (powers of two instead of the extensive copying of qubits), and is quantum hardware dominant (one classical variable instead of many). Altogether, this makes QAE ideal for calculating ground and excited electronic states. The researchers demonstrated these calculations across a variety of small molecular systems.

Although the QAE is viable and offers accurate energies for small molecules, the researchers found large energy errors for larger systems, which was attributed to the qbsolv software. The researchers recommended methods for improving the accuracy, such as reducing the size of the problem and taking advantage of larger qubits as quantum computing progresses.

Knowledge of ground and excited energies and states from this research enables the investigation of chemical and industrial processes (e.g., catalysis, electrochemistry, polymerization, and photochemistry, etc.) as well as the discovery of new materials and catalysts.

Funding and mission

Research presented in this article was supported by the Laboratory Directed Research and Development (LDRD) program of Los Alamos National Laboratory. This work was conducted, in part, at the Center for Nonlinear Studies and the Center for Integrated Nanotechnologies (CINT), U.S. Department of Energy (DOE), Office of Basic Energy Sciences user facility at LANL. The research supports the Laboratory’s Global Security mission area and the Integrating Information, Science, and Technology for Prediction capability pillar.

Reference: A. Teplukhin (T-1), B. K. Kendrick (T-1), S. Tretiak (T-1), and P. A. Dub (C-IIAC). “Electronic structure with direct diagonalization on a D-Wave quantum annealer.” arXiv preprint arXiv:2009.01373 (2020).

Technical contacts: Brian Kendrick and Pavel Dub

Materials Science and Technology

Breakthrough on recompaction of spall damage on second shock

The cover of the Journal of Applied Physics features Los Alamos science on new defect-free grains that nucleated in the recompacted region essentially “healing” the material.

Spall fracture is a high strain-rate damage phenomenon associated with shock or impulsive loading events. While much research exists on the factors influencing the failure process, few studies have been performed detailing what happens when a material containing spall damage is subjected to a second shock. The conditions that generate spall in real-world applications are rarely isolated, with secondary loading events expected to occur (e.g., armor subjected to projectiles or firearms).

In research aimed at understanding—and ultimately controlling—the performance of materials subjected to extreme environments, MST researchers conducted a series of gas-gun flyer-plate impact experiments using copper samples. Their work sought to confirm that a second shock loading event could recompact existing spall damage and, if so, characterize the resulting microstructure to determine whether the compacted region has any form of bond.

In work featured on the cover of the Journal of Applied Physics, the researchers presented conclusive results, in copper targets confirmed to contain spall damage, that relatively modest shock stresses of 2–3 GPa can fully recompact the damage back to a state of zero porosity. These results are significant because they clearly show that metals driven by in-contact explosive can damage and subsequently recompact.

High-magnification imaging of the recompacted region with electron microscopy techniques revealed that where the initial spall voids have compacted, a combination of plastic work and high temperatures has allowed recrystallization or formation of defect-free grains to occur. As such, the damaged copper is now both free of voids and has formed a new microstructure in this previously damaged region akin to welding as opposed to simply pushing the free surfaces together.

This “healed” region would be expected to have mechanical strength, and future works will involve carefully sectioning small tensile-test samples from the recompacted region to test this hypothesis. Materials with a far higher melting point (and, therefore, recrystallization temperature) are also being studied.

The study leveraged the Laboratory’s decades of dynamic materials research and its expertise and capabilities in materials characterization, electron microscopy, and photon Doppler velocimetry, and gas gun experimental facilities. By understanding the process, structure, properties, and performance of materials in extreme conditions, researchers aim to ultimately control a material’s performance.

Funding and mission

The work, which was funded by Science Campaign 2 (LANL Program Manager Dana Dattelbaum) supports the Laboratory’s Nuclear Deterrence mission area and the Materials for the Future science pillar, in particular its Defects and Interfaces and Extreme Environments science themes.

Reference: “Shock recompaction of spall damage,” Journal of Applied Physics 127 (2020).

Researchers: David Jones, Saryu Fensin, Benjamin Morrow, Daniel Martinez, and Robert Hixson (all Materials Science in Radiation and Dynamics Extremes, MST-8). Roberta Beal and A. Samuel (both MST-8) prepared the microscopy samples.

Technical contacts: David Jones and Saryu FensinWang co-edits special Materials issue: Helium effects on materials in extreme environments

Yongqiang Wang (Materials Science in Radiation and Dynamics Extremes, MST-8) collaborated with Khalid Hattar (Sandia National Laboratories) to produce a special issue of Materials.

The issue collectively highlights research into the effects of helium on materials in irradiation environments, such as advanced structural steels in fast fission reactors, plasma facing and structural materials in fusion devices, spallation neutron target designs, energetic alpha emissions in actinides, helium precipitation in tritium-containing materials, and nuclear waste materials.

The researchers were chosen as guest editors because of their extensive experience in radiation damage, ion–solid interactions, in situ characterization, and nanomechanics.

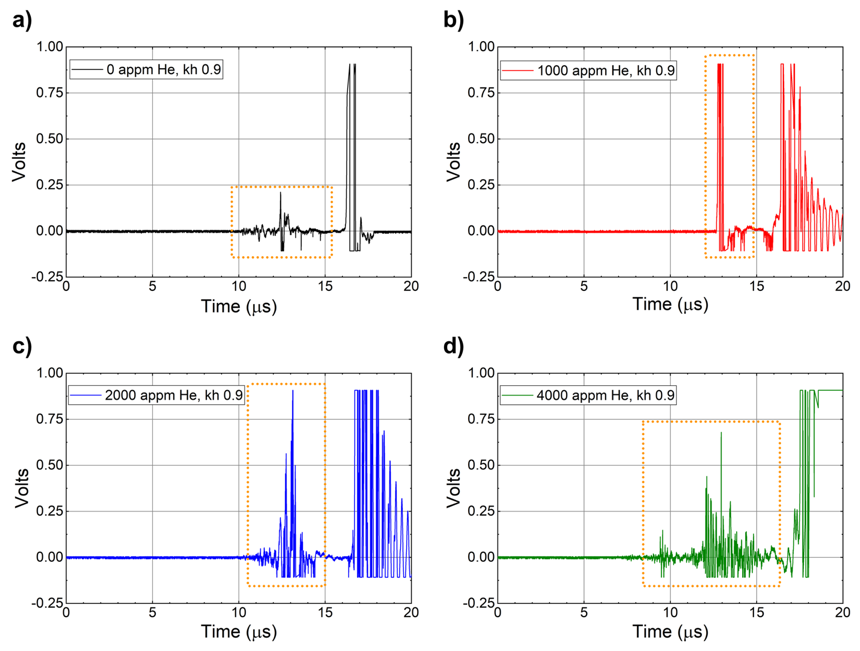

Voltage time history as a function of helium concentration. The plots show ejecta is produced much earlier in time as helium concentration increases, and ejecta is produced for a longer period of time, likely leading to higher amounts of ejecta as helium concentration increases. Kh refers to the size of the perturbation that was machined on the surface of the sample. Here the wavelength (lambda) of 65 microns was used, where kh=2Pih/lambda.

Within the 13-article issue, Los Alamos researchers contributed six separate articles.

- “The role of helium on ejecta production in copper,” by Saryu Fensin, David Jones, Daniel Martinez, Calvin Lear (all from MST-8); and Jeremy Payton (Neutron Science and Technology, P-23)

- “In-situ helium implantation and TEM investigation of radiation tolerance to helium bubble damage in equiaxed nanocrystalline tungsten and ultrafine tungsten-TiC alloy,” by Osman El-Atwani, Kaan Unal, Saryu Fensin, Stuart Maloy (all MST-8); William Streit Cunningham (Stony Brook University); and Jonathan Hinks and Graeme Greaves (University of Huddersfield)

- “An overview of recent standard and accelerated molecular dynamics simulations of helium behavior in tungsten” by Luis Sandoval, Danny Perez, Arthur F. Voter (all Physics and Chemistry of Materials, T-1); and Blas P. Uberuaga (MST-8)

- “Effect of helium on dispersoid evolution under self-ion irradiation in a dual-phase 12Cr oxide-dispersion-strengthened alloy,” by Hyosim Kim (MST-8); Jonathan G. Gigax (Center for Integrated Nanotechnologies, MPA-CINT); Tianyao Wang, Frank A. Garner, Lin Shao (all from Texas A&M University); and Shigeharu Ukai (Hokkaido University)

- “Swelling and helium bubble morphology in a cryogenically treated FeCrNi alloy with martensitic transformation and reversion after helium implantation,” by Di Chen, Yongqiang Wang (MST-8); Feifei Zhang, Lumin Wang (University of Michigan); Lynn Boatner (Oak Ridge National Laboratory); and Yanwen Zhang (University of Tennessee)

- “Investigating helium bubble nucleation and growth through simultaneous in-situ cryogenic, ion implantation, and environmental transmission electron microscopy,” by Caitlin A. Taylor (formerly Sandia National Laboratories, now MST-8); Samuel Briggs, Anthony Monterrosa, Joshua D. Sugar, David B. Robinson, Khalid Hattar (all Sandia National Laboratories); and Emily Aradi, Graeme Greaves, and Jonathan A. Hinks (University of Huddersfield)

Overall, the articles focus on new irradiation material research activities and novel material ideas using experimental or modeling approaches.

Funding and mission

The collective research supports the Laboratory’s Nuclear Deterrence mission area and the Science of Signatures capability pillar.

Reference: Yongqiang Wang and Khalid Hattar. “Radiation damage in materials—helium effects,” Materials 13 (9), (2020). doi: 10.3390/ma13092143

Technical contact: Yongqiang WangPhysics

New details on the nature of thermal interfaces in dynamic compression experiments

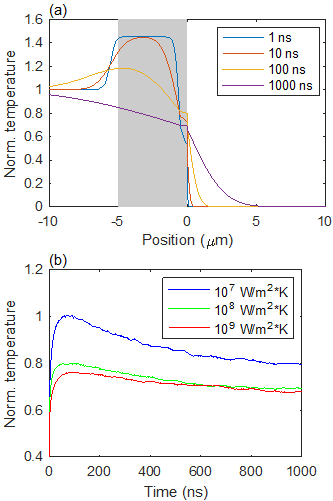

The initial (top, normalized) temperature profile created by dynamic compression spatially varies across the measurement interface at 0 micron. Time-evolution of the temperature at that interface (bottom) shows how thermal diffusion produces interface temperatures that vary in comparison to the bulk thermodynamic material state (set to unity) of interest.

In work chosen as an Editor's pick in the Journal of Applied Physics, Tom Hartsfield (Neutron Science and Technology, P-23) and collaborators from the Nevada National Security Site and Sandia National Laboratories showed that complex shockwave interactions rapidly create and leave behind a complex local thermal profile across the measurement interface. Subsequent thermal diffusion then produces a time-varying temperature measurement with a range of particular signatures.

For materials under dynamic compression, time-resolved temperature measurements are essential to understanding the physics influencing phenomena ranging from equation of state to phase transition and chemical reaction. Until now, proper understanding of the temperature profile along the compression axis in dynamic compression experiments has been unclear, as has relating that temperature profile to the actual measured interface between different materials. There is also a fundamental disconnect between the measured interface temperature and the bulk temperature of interest.

“Temperature is important but very hard to measure correctly in dynamic compression experiments. Getting it right requires carefully investigating a lot of details. This paper explains a few details that we didn’t quite have a handle on before and shows how to attack a class of difficult analyses.” Hartsfield said.

Interface physics are key to material behavior

Focusing specifically on the complex measured temperature profile of samples with multiple thermal interfaces, the researchers found that understanding the interface physics at play is even more important than precise temperature measurement when seeking to understand and predict the behavior of materials in extreme environments.

The published calculations support the presumed effectiveness of the technique of measuring the temperature of a sample via light passed through an attached optical window. Critically, the window must be bonded to the sample with epoxy that maintains a thermal barrier between sample and window. Conducting a series of complex multi-layered experiments, firing a sample into a window covered by a thin coating, produced results that at first puzzled the team.

Comparing the results of their experiments to numerical analysis of the loading path and thermal diffusion at the measurement interface, the researchers discovered that shockwave interactions rapidly create and leave behind a complex local thermal profile.

At the measurement point, material temperature subsequently evolves at longer characteristic timescales throughout the duration of the experiment. As a result, seemingly subtle changes in experiment geometry lead to very different temperature profiles that vary in time. This insight into the thermal and mechanical physics driving interface properties in dynamic compression experiments allowed the researchers to explain how the temperature of that interface relates to the fundamental bulk thermodynamic state that is used to improve the material models in the Laboratory’s hydrodynamics codes.

Funding and mission

The Los Alamos portion of the research was funded by the Dynamic Materials Properties Campaign (LANL Program Manager Dana Dattelbaum, Project Leader Garry Maskaly). The research supports the Laboratory’s Nuclear Deterrence mission area and the Materials for the Future capability pillar.

Reference: “Thermal interfaces in dynamic compression experiments,” Journal of Applied Physics, (2020). https://doi.org/10.1063/5.0012524

Researchers: Thomas Hartsfield (P-23); Brandon LaLone, Gerald Stevens, Lynn Veeser (Nevada National Security Site); Dan Dolan (Sandia National Laboratories).

Technical contact: Thomas HartsfieldProposal Call

Laboratory Directed Research and Development Early Career Research Proposal Call

The Los Alamos Laboratory Directed Research and Development (LDRD) Program Office released the fiscal year 2021 Early Career Research call for proposals. Early Career Research awards are designed to strengthen the Laboratory’s scientific workforce by providing support to exceptional researchers during their crucial early career years. Those selected for funding are well positioned to stimulate research in disciplines important to the Laboratory.

LDRD defines early career as researchers who have received their highest degree within the last 10 years as of the date of the call for proposal (excluding absences for family or medical leave) and have been hired as Laboratory staff no more than three years prior to the call. This definition applies to both U.S. citizens and international candidates.

Proposals can be submitted within five focus areas:

- Information Science and Technology

- Materials for the Future

- Science of Signatures

- Nuclear and Particle Futures

- Complex Natural and Engineered Systems

Proposals are due October 7, 2020. Candidates will submit their proposals via the LDRD Q system online. Project start dates will range from January to June 2021, and project budgets will be $225K per year for two years.

Announcement of the award recipients is anticipated November 20, 2020.

About LDRD

The heart of the LDRD program is high-risk, high-reward research that creates innovative technical solutions for some of our nation’s most difficult challenges.

The program follows strategic guidance derived from the missions of the U.S. Department of Energy, the National Nuclear Security Administration, and the Laboratory. To execute that strategy, the LDRD program creates a free market for ideas that draws upon the bottom-up creativity of the Laboratory’s best and brightest researchers.

The combination of strategic guidance and free-market competition provides a stream of capabilities that position the Laboratory to solve our most difficult mission challenges.

Sigma

First-ever high-performance MgO ceramic substrate via tape casting

With a LANL logo business card used as a background, this image shows the transparency of the pressureless sintered substrate after hot-isostatic-pressing at 1650 °C and 207 MPa in argon. The obvious translucency proves it is a fully dense structure.

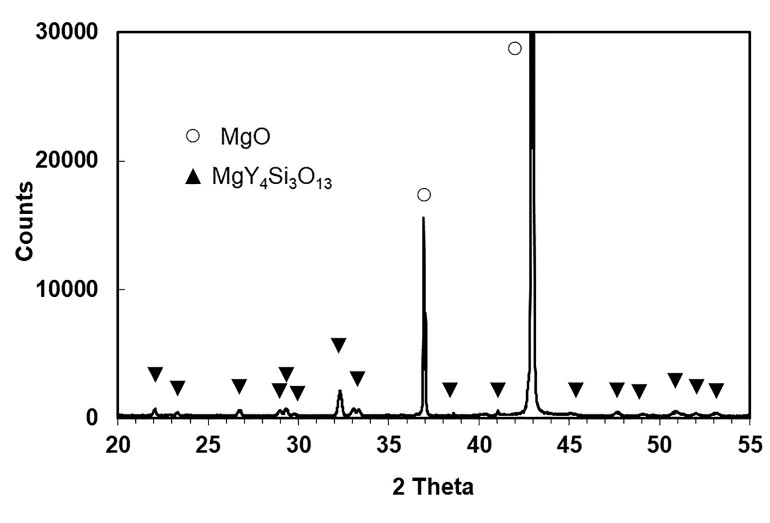

An x-ray diffraction pattern that shows MgO is the main phase while both Y2O3 and SiO2 sintering aids react with MgO to form MgY4Si3O13 as the second phase.

Using a novel tape-casting formulation and process, Los Alamos researchers in Sigma Division working with collaborators developed a high-density magnesium oxide (MgO) ceramic substrate.

The excellent low dielectric constant and low-loss tangent of the developed MgO substrate will have a transformational impact on a wide range of applications, including satellite, high-power microwave, microelectronic, optoelectronic, powder modules, areospace, and defense.

A manufacturing breakthrough

MgO is sought for its unique properties, such as high-temperature insulation that results from its high melting point, high thermal conductivity, and high breakdown potential. Despite the desire to produce an MgO ceramic, the manufacturing of such a material is quite challenging.

Sigma has long been a hub for manufacturing breakthroughs, and that’s what it took to bring a viable MgO ceramic substrate to fruition. The main challenge was overcoming MgO’s tendency to form unwanted hydroxide, which the Sigma researchers avoided through the use of isopropyl alcohol and xylenes.

The researchers used Y2O3 and SiO2 as sintering aids during the tape casting manufacturing process. The aids react with MgO to make MgY4Si3O13 during pressureless sintering. The product was then processed via hot-isostatic pressing (HIP) in argon to deliver a fully dense structure. Scanning electron microscopy and energy dispersive spectroscopic analyses confirmed the fully dense structure and showed that MgY4Si3O13 is located at the MgO grain boundary. In the final product, the MgO is the primary phase, and the MgY4Si3O13 is the secondary phase.

A better process and product

Before Sigma’s innovative tape-casting process, most MgO substrates were produced via machining from a single crystal, which is an expensive process strongly dependent on the orientation of the cut. Sigma’s novel tape-casting method is less expensive, and it produces an MgO ceramic substrate with unsurpassed refractive index, as-fired surface finishing, and thermal properties.

The MgO tape produced was uniform and free of cracking. It was both smooth and extremely crystalline.

The technology was enabled by the Lab’s expertise in advanced manufacturing and the ceramic processing manufacturing capabilities in the Sigma Complex.

Funding and mission

This work is a joint development between Los Alamos, J. A. Woollam Corporation, and Sienna Technologies Inc. This work was supported by the PIT Technology program (LANL Program Manager Francisca Rein Rocha). The research supports the Lab’s Nuclear Deterrence mission area and the Materials for the Future capability pillar.

Reference: “Tape casting and characterizations of MgO ceramics,“ Journal of American Ceramics Society (2020).

Researchers: Chris Chen (Fabrication Manufacturing Science, Sigma-1), Timothy Baker (LANL), Ron Synowicki (J.A. Woollam Co.), Eric Tegtmeier, and Robert Forsyth (Finishing Manufacturing Science, Sigma-2), Ashley Bissell, Alex Orlowski (Sienna Technologies, Inc.), James Christopher (Sigma-1), Ender Savrun (Sienna Technologies, Inc.).

Technical contact: Chris Chen