Being Tenacious: Tana Cardenas

Lab Character: Who We Are

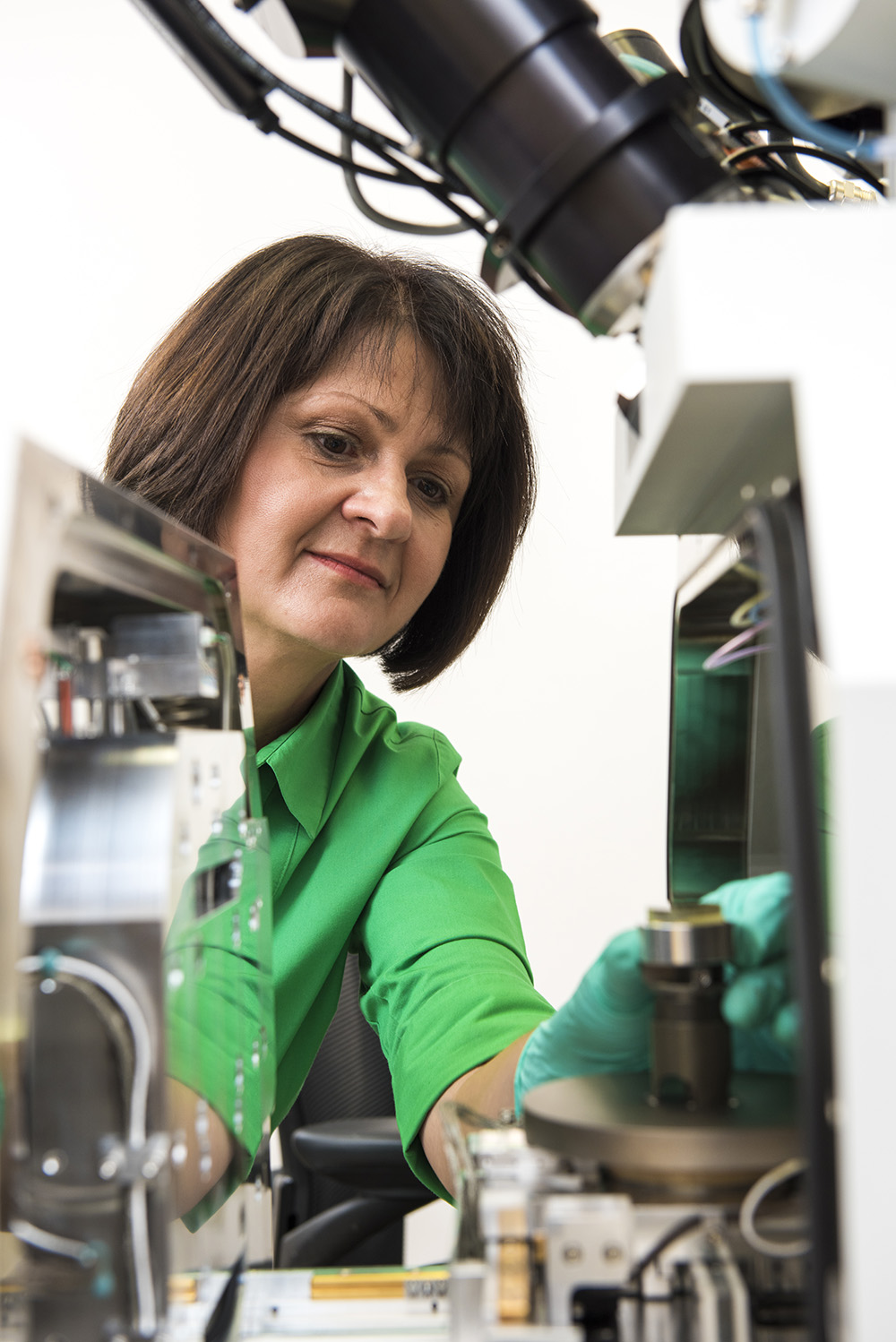

Veronica Livescu

Analyzing the microstructure of materials in support of Lab and NNSA programs

Veronica Livescu’s career has taken quite a turn since she earned her master’s in aerospace engineering in Romania in 1991.

On her way from Bucharest to the Laboratory’s Materials Science in Radiation and Dynamics Extremes group (MST-8), she changed not only countries but also disciplines, transforming herself from a mechanical engineer to a materials scientist.

The changes began as soon as she graduated.

"Jobs in the aerospace industry were hard to find at that time,” she said, “so for six years I worked for the Bucharest subway system—a combined engineering and programming position."

But Livescu wanted research opportunities and followed that desire to New York State and the University of Buffalo– SUNY, where she earned a second master’s (2001), this time in biomedical engineering, working with shape-memory alloys used in novel stents for treating arterial aneurysms.

That master’s work and then a job with a manufacturer of medical devices moved her to materials science and subsequently to Los Alamos.

On staff since 2005, Livescu is a member of MST-8’s Dynamic Materials Properties team—a critical member, according to team leader George T. (Rusty) Gray III.

"The team measures the static and dynamic properties of a large range of materials,” said Livescu. “We’re looking at the results of dynamic shock loading in metallic structures and at the influence of materials’ internal structure on deformation, void nucleation and growth, and ultimate failure."

Lab Character

Watch for more profiles of Lab employees who exemplify the nine positive character traits that personify who we are, past and present:

- Innovative

- Agile

- Passionate

- Responsive

- Tenacious

- Trusted

- Principled

- Scientific

- Iconic

Discover more about your colleagues and gain insight into their journeys . . .

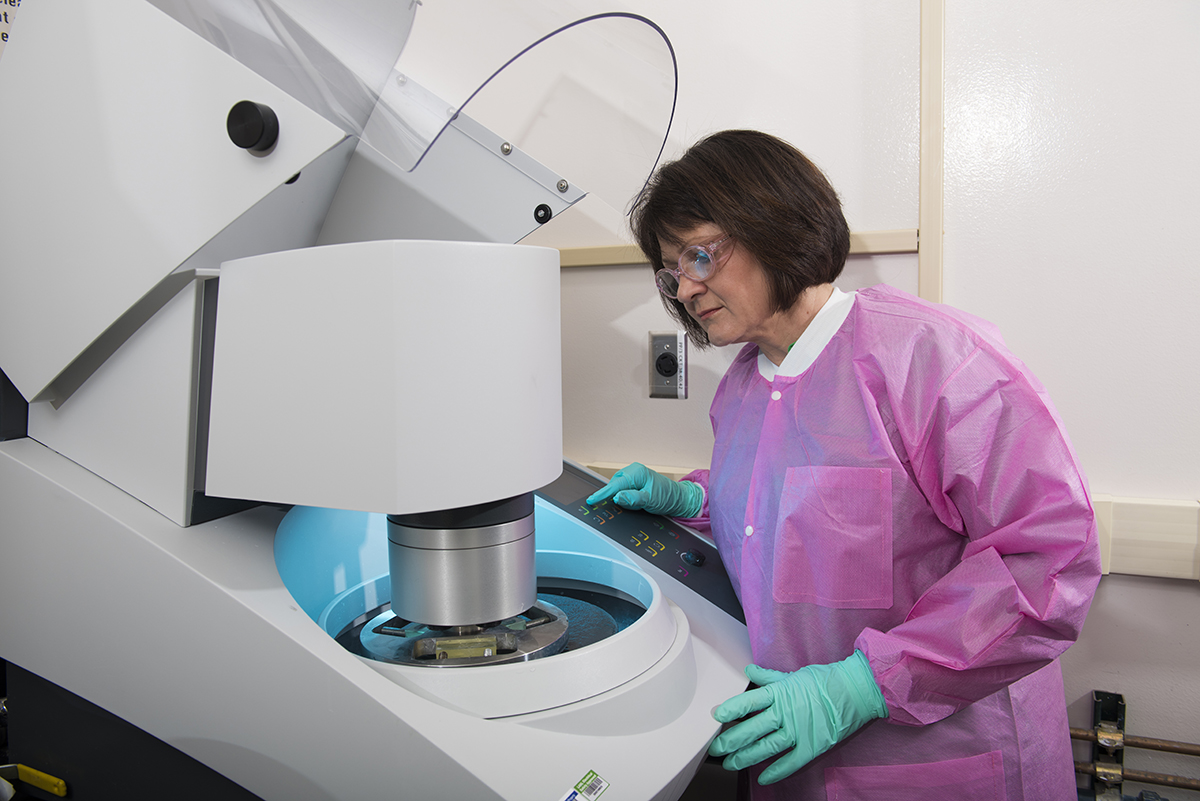

She uses optical microscopy, scanning electron microscopy, and electron backscatter diffraction (EBSD) to characterize a material’s microstructure—the size and crystallographic orientation of the material’s grains, the interfaces between the grains, and the presence of porosity (small voids) and/or impurities.

Bineh Ndefru (pictured in first photo), who joined the Lab in 2016 as a post-baccalaureate, appreciates her mentor.

"It’s been extremely rewarding working with Veronica, as she is very knowledgeable about the various tools that we use in the labs and is always willing to explain concepts and broader project goals in detail and with clarity," Ndefru said. "She’s a great mentor not only for her excellent communication of research details, but also because of the time she spends getting to know her students on a personal level."

Ndefru is learning how to characterize deformation twinning in titanium resulting from quasi-static and dynamic loading, as well as deformation modes in other materials. She's also working with Livescu to characterize additively manufactured (3D printed) metals, including tantalum and steel alloys.

"Every material is different,” said Livescu, “and despite the fact that we understand the importance of a material’s structure on its properties, we still have a lot to learn about the mechanisms involved in the generation of damage under shock-loading conditions.

Detecting subtle changes in a material’s microstructure can unveil critical information regarding the material’s response to loading, so when possible, she focuses on using software that generates three-dimensional volumes from the EBSD analysis to create material models.

Because processing greatly influences microstructure and therefore a material’s stress response, Livescu and her colleagues have recently chosen two kinds of samples to work with, some that were traditionally manufactured—wrought and annealed—and others that were created by additive manufacturing, in which powdered metal is melted as it gets deposited in ultrathin layers.

The microstructure of the two, she said, is quite different. "The additively manufactured materials have a much finer grained, more complex microstructure, exotic and challenging at the same time. In addition to the polycrystalline microstructure, the layer-by-layer deposition results in a macroscale pattern, which looks almost like rows of fish scales."

Livescu analyzes the samples both before and after the shock-loading experiments, many of which she and the team do themselves, using a gas gun and split Hopkinson pressure bar for one-dimensional shocks and mechanical frames for the slow, steady pressure of quasistatic loading.

Collaboration is the reason for the efforts of Livescu and the team. Their work supports Theoretical Division’s development of models and simulations to better predict how materials behave under extreme conditions.

The work is important to stockpile stewardship and is one of DOE’s scientific grand challenges.

Livescu said she never expected to do such work back in 1991, before she started down the path to her current job. "I never in my life thought that I would work for Los Alamos National Laboratory, but I saw opportunities and took them. It all turned into something great."