Being Innovative: Paul Dowden

Lab Character: Who We Are

Paul Dowden

Constructing a unique laser application for research

Lab Character

Watch for more profiles of Lab employees who exemplify the nine positive character traits that personify who we are, past and present:

- Innovative

- Agile

- Passionate

- Responsive

- Tenacious

- Trusted

- Principled

- Scientific

- Iconic

Discover more about your colleagues and gain insight into their journeys . . .

From his wallet, Paul Dowden produces a photo of his daughter, then about 4 years old. She’s perched in the driver’s seat of a 1,400 horsepower alcohol-fueled dragster he built from scratch.

Dowden has applied his skillful hands to cars for decades. He’s worked as an auto and diesel mechanic and as a hot rod enthusiast, doing his own fabrication, electronics, and engine and transmission building.

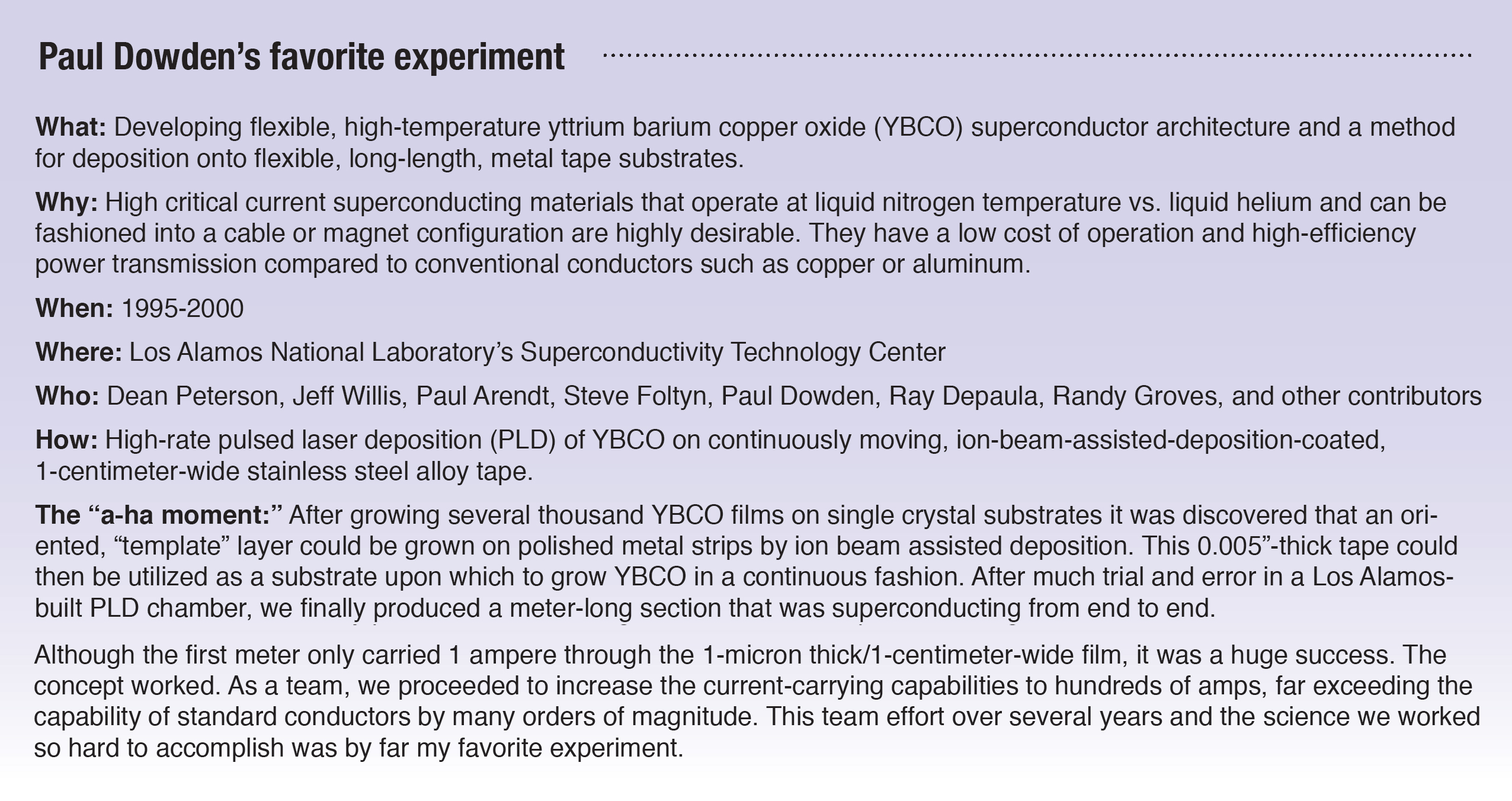

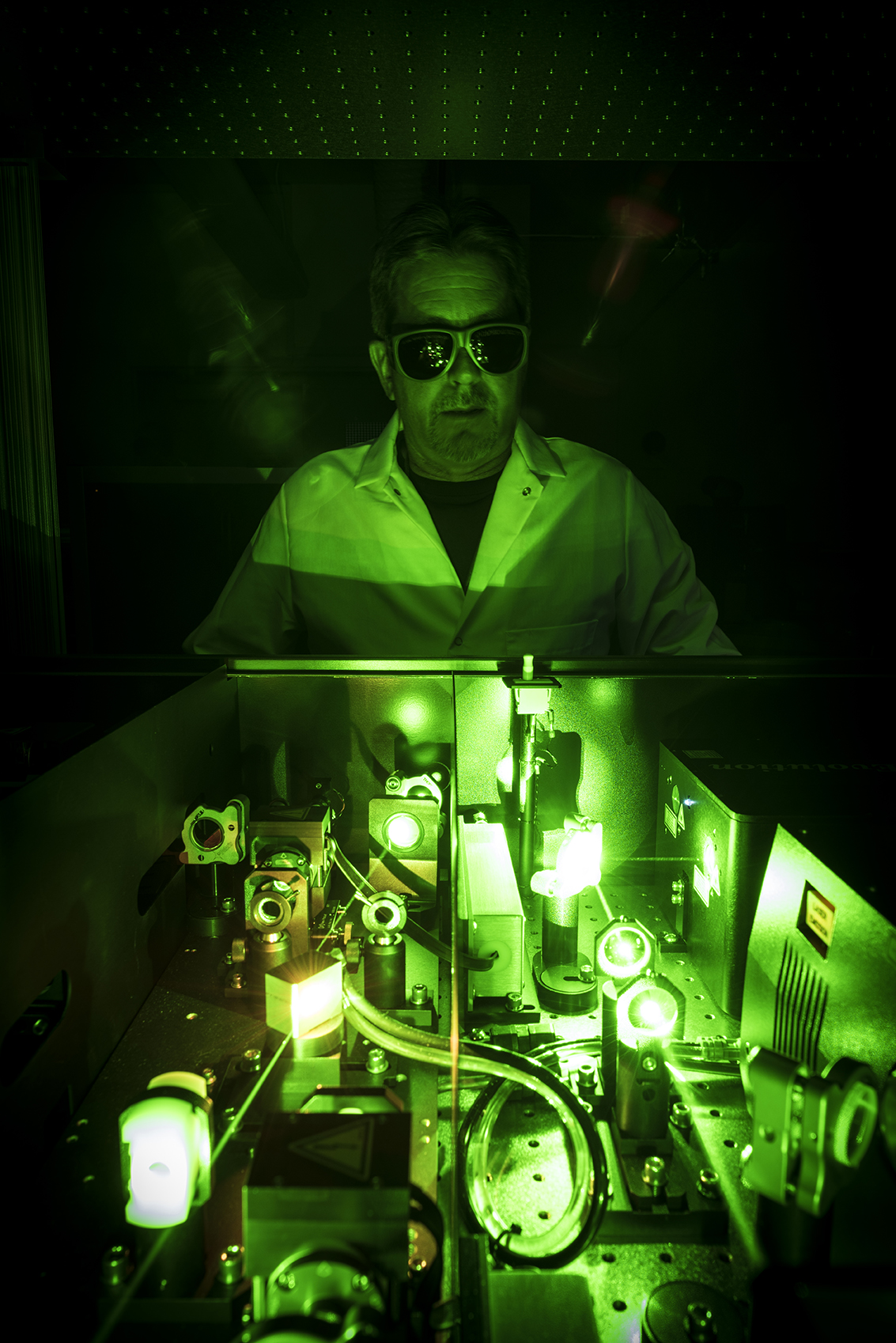

That same tinkering streak serves him well today as he oversees all pulsed laser deposition (PLD) operations for the Center for Integrated Nanotechnologies at Los Alamos (MPA-CINT). Innovation drives his contributions to a range of projects, from chemical lasers to the R&D 100 award-winning flexible superconducting tape.

Dowden is more than a mechanical engineer, explains longtime collaborator and former CINT Center Leader Quanxi Jia (The State University of New York at Buffalo). “He knows about the electronics, mechanics and vacuums—and can get his hands almost everywhere. I don’t see many techs who are so versatile or have such broad experience.”

The inspiration to apply his talent for building hot rods to building lasers happened during freshman orientation at Indiana’s Vincennes University.

Dowden walked out of the school’s mechanical engineering department mid-orientation and happened upon the laser and electro-optics department. One professor had worked at Los Alamos National Laboratory, which led to Dowden’s discovery of the Department of Energy-funded Antares Laser Research program, a large laser system built to achieve fusion.

After graduating top in his class, he joined the Lab in 1983 as a contract electronics technician. When a position to complete Antares’s multi-line carbon dioxide oscillator materialized, he jumped on it, becoming a Los Alamos laser optical technician.

Innovative thinking makes for a one-of-a-kind system

Now a technologist in MPA-CINT, Dowden’s innovative thinking shined through when he developed and patented pulsed laser deposition (PLD) system components, which took him years to perfect, making for a one-of-a-kind system that’s just gone online.

Dowden’s PLD systems and improvements bring a new capability to CINT, a DOE Office of Basic Energy Sciences national user facility jointly operated by Los Alamos and Sandia national laboratories. The instruments are available to outside researchers through CINT user agreements.

This versatile system allows researchers to grow thin films ranging from tens of nanometers to micrometers in thickness. It’s ultra-customizable, using multiple targets, different gases, unique wavelengths, specific configurations and offering a variety of laser parameters. The system grows functional materials ranging from oxide thin films to heterostructures, superlattices and nanocomposites—which have applications in high sensitivity sensor devices, storage devices with ultra-low power consumption, and energy storage with high power density.

New beamline overcomes drawbacks of traditional lasers

Putting to work his expertise in complex mechanical and optical systems, Dowden conceptualized and constructed a stabilized, imaged beamline for PLD systems that was key to overcoming the drawbacks of a traditional, single lens focus for repeatable PLD film growth. The new beamline, part of the larger system, earned him a 2016 U.S. Patent. For the system, Dowden also created a patent-pending ultra-clean substrate heating device, which operates without any braze materials and reaches 1000 ºC.